Our Certification

With advanced technology and continuous R & D investment, our products have obtained a large number of patent certificates , CE certificate etc.

Pneumatic vacuum feeding machine is the use of compressed air through the vacuum generator to produce high vacuum to achieve the conveying of materials

Our Experience

9+

YEARS OF EXPQuality Assurance

Video inspection provided before delivery

Fast delivery

Standard machines in stock and various shipping options

Support warranty

12 months from delivery date

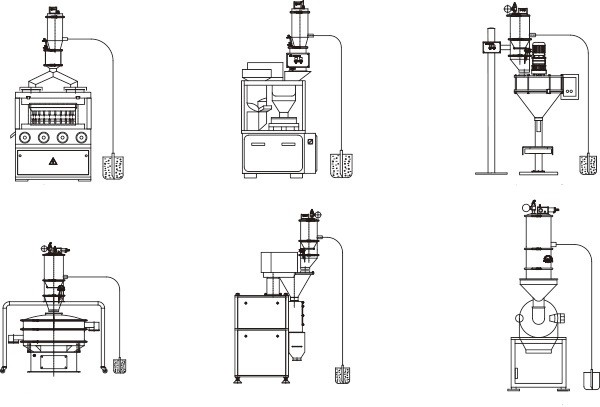

Pneumatic vacuum feeding machine is the use of compressed air through the vacuum generator to produce high vacuum to achieve the conveying of materials, does not need mechanical vacuum pump, has the advantages of simple structure, small size, maintenance free, low noise, convenient control, eliminate material static electricity and so on. The high vacuum generated by the vacuum generator, so that the conveying material to eliminate the stratification phenomenon, to ensure the uniformity of the mixed material ingredients, is the tablet press, capsule filling machine, dry granulation machine, packaging machine, crusher, vibrating screen and other mechanical automatic feeding equipment.

When the compressed air is supplied to the vacuum generator, the vacuum generator generates negative pressure to form a vacuum air flow, and the material is sucked into the suction nozzle to form a material air flow, which reaches the bin of the feeder through the suction tube. The filter completely separates the material from the air. When the material is filled with the bin, the controller will automatically cut off the air source and the vacuum generator will stop working. At the same time, the bin door will automatically open and the material will fall into the hopper of the equipment. At the same time, compressed air passes through the pulse blowback valve to automatically clean the filter. When the time is up or the material level sensor sends out the feeding signal, the feeding machine will be automatically started.

Vacuum feeder is produced by the rf generator vacuum negative pressure, which will be on suction vacuum feeder tube material from material storage VAT will suck in warehousing, again through the filter to gas separation, feeding time is decided by the controller, absorb over, pneumatic device doors will open the door into the related equipment, reverse blowing device will blow adsorption on the filter powder, the powder removed, Then close the feed door again and the next cycle begins.

| Model | QVC-1 | QVC-2 | QVC-3 | QVC-4 | QVC-5 | QVC-6 |

| Capacity(kg/h) | 350 | 700 | 1500 | 3000 | 6000 | 9000 |

| Air consumption (L/min) | 180 | 360 | 720 | 1440 | 2880 | 4320 |

| Air pressure | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| Dimension | 140x560 | 213×720 | 290×850 | 420×1150 | 420×1150 | 420×1350 |

With advanced technology and continuous R & D investment, our products have obtained a large number of patent certificates , CE certificate etc.